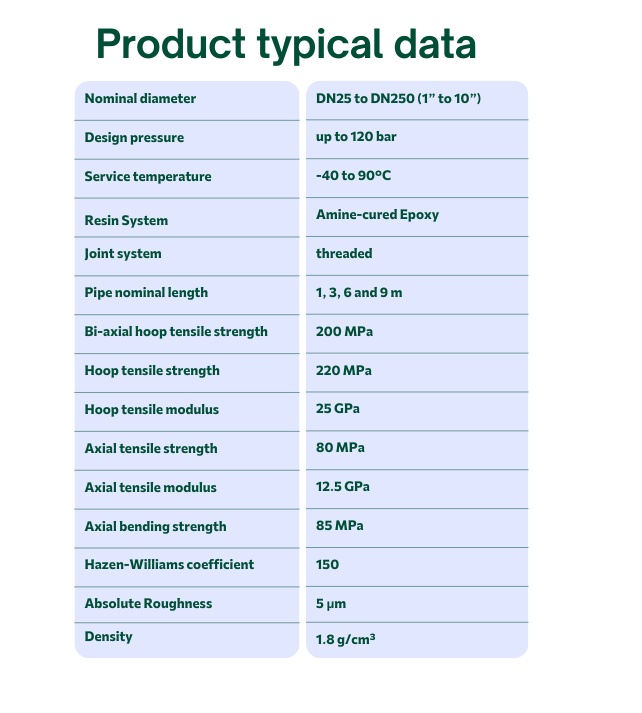

FLOXY® high pressure GRE pipes and fittings for high pressure oil & gas field and industrial applications are manufactured in nominal sizes from 25 to 250 mm (1 to 10 inch) and can be used at nominal pressures up to 120 bars with service temperatures up to 90°C.

Typical application includes the following:

FLOXY® high pressure GRE products comply with the requirements of API 15HR and ISO 14692 standards. The long-term performance of the pipes and fittings is determined according to ASTM D2992 standard (method B), considering a 20-year design life.

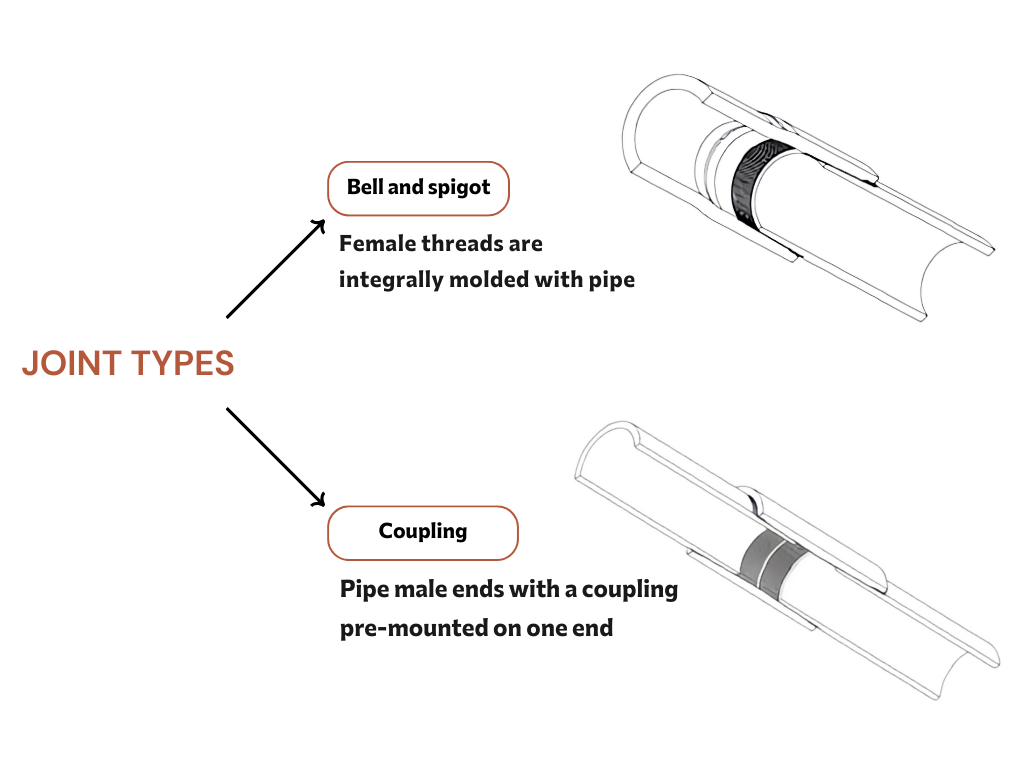

GRE products are manufactured in filament winding process and incorporate high strength continuous glass fiber roving impregnated by a corrosion resistant epoxy resin system on to a steel mandrel. The material and winding angle are carefully selected to result the strongest and most thermal and corrosive resistant fiberglass piping system. Full range of fittings with API 5B threads including Elbows, Tees, Reducers and Flanges are available.

TehranOffice

No.23, 19th St.,South Gandhi St.,

Vanak Sq.,Tehran, IRAN

Factory

NO.6 Sanat,Sanat Square,

Caspian industrial town,25 km of

Tehran-Qazvin

freeway,Tehran,IRAN

info@bkagrp.com

phone

+98(21)88661485

info@bkagrp.co

phone

+98(21)88661485